As an ISO 9001 certified company, we ensure from the development to the finished product with the utmost quality and reliability. At our company headquarters in weather are Wengern, we are able to, all manufactured parts to a comprehensive quality control. Part of our products, we contribute to the production of renewable energies. Wind turbines around the world are working with our hydraulic or mechanical shrink discs. We work for a cleaner future.

Our technological developments in the area of shaft and rudder systems, promote seas trade and travel across the world and secure the basis for the global exchange of goods. Strength and endurance are unknown to us. Our clamping sets and flange couplings, conveyor systems allow the removal of the important raw materials for our daily life.

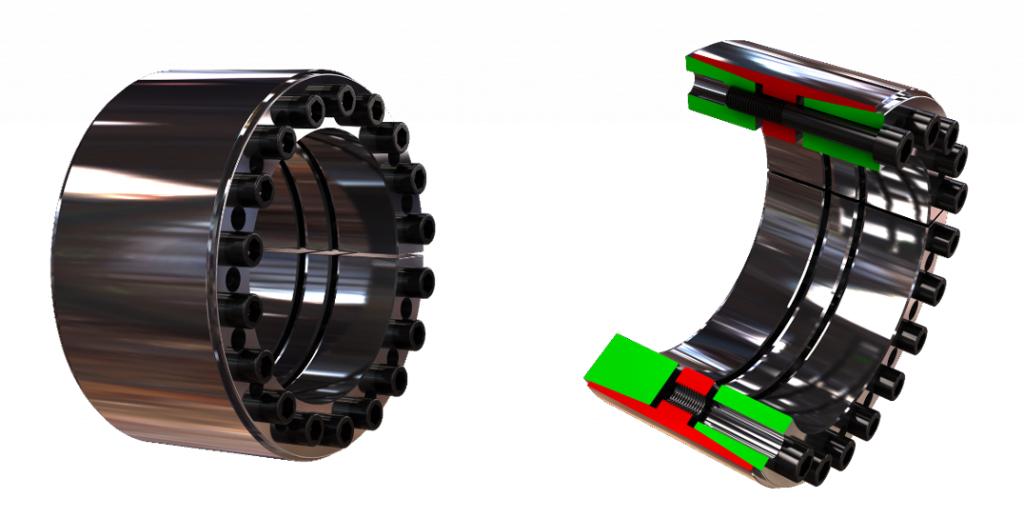

Locking assemblies

Locking assemblies are used in mechanical engineering to create a frictional shaft-hub connection. The Locking assemblies connects the hub of a gear, for example, to a shaft by means of a frictional connection. This backlash-free connection between shaft and hub allows reliable transmission of torques as well as axial forces. Depending on the design of the clamping set, high bending moments can also be transmitted with this type of connection.

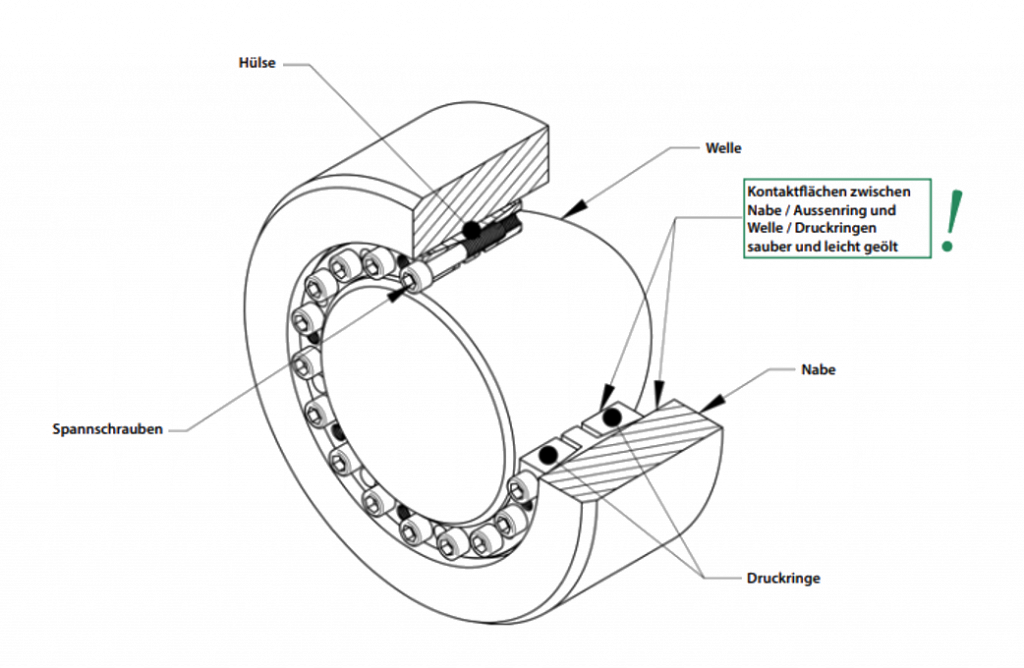

Locking assemblies (also called "conical clamping elements" or "internal clamping elements") consist of one or two conical pressure rings and a conical clamping sleeve, depending on the design. By tightening the clamping screws with the specified tightening torque, the conical pressure rings are drawn onto the conical surface of the clamping sleeve. This process creates a radial force both inward and outward. While the outside diameter increases, the diameter inside the clamping sleeve decreases. This creates a frictional connection between the locking assembly (cone clamping element) and the shaft as well as the hub.

In contrast to a groove in conventional keyway connections, the stresses at the shaft are distributed evenly over the entire contact surface of the locking assembly. The uniform stress distribution produces a reliable, free positional and, above all, wear-free connection. This often leads to a smaller shaft size and therefore reduced weight of the design.

Locking Assemblies are available in a wide variety of designs and types. In addition to the torsional or bending moments to be transmitted, the available installation spaces as well as loads also play an essential role for the right product selection. No matter whether self-centering, low surface pressure, high speeds or stainless steel versions for the food- and chemical-industry - the product portfolio of TAS Schäfer GmbH offers a suitable solution for all areas.

Clamping sets are divided into two groups:

Die The more compliant cone locking assemblies and the the rigid cone locking assemblies.

The more compliant locking assemblies have a total of four conical functional surfaces and several individual components. Due to the design and the resulting larger cone angle, the compliant cone locking assemblies are not self-locking. This means that it is not necessary to press off the thrust rings during disassembly. Since the pressure rings are not moved axially on the shaft during assembly, there is no axial displacement between the shaft and hub.

Rigid cone clamping elements have only one or two conical functional surfaces. This results in different technical properties than the more compliant cone locking assemblies. Due to their design, rigid cone clamping elements can transmit higher bending moments. In addition, this design has the property of better self-centering and self-locking. Another property is that the clamping screws are not subjected to any further loads by incoming forces during operation after assembly. This increases the safety and service life of the rigid cone clamping elements.

Typical examples for the rigid cone clamping elements are the series TAS 3012 and TAS 3006

In general, the various locking assemblies can be subdivided according to the type of application and the available installation space. Short locking assemblies are usually able to absorb low to medium torsion and bending moments. Whereas wide locking assemblies are used for high to very high torsion and bending moments. The properties of individual locking assemblies with regard to transmissible torque and bending moments as well as their installation length can be found in the product overview below. Further properties, such as self-locking, self-centering or possible bending moment component of the locking assemblies can be found on the respective product pages in the catalog.

For industry, the performance capabilities of individual components, cost advantages, reduction of assembly times or increased lifetime play an important role in the fastening of components on rotating shafts.

A conventional method in the past was the connection via a keyway. With this type of connection, a keyway/groove is milled into the shaft. This is also done in the hub. However, milling these keyways is costly and time-consuming. Another disadvantage is also the reduction of the transmittable torque due to the weakening of the shaft. Often, a splined connection also creates movement and eventual backlash, which can affect the accuracy of a machine system and create the risk of failure.

With a friction-locked shaft-hub connection by using a locking assembly, this risk can be avoided because there is no play. The use of a locking assembly therefore ensures precision and safety. In addition, costly manufacturing processes, such as milling or grooving, can be saved.

Another advantage of using a TAS Schaefer locking assembly is the positioning on the shaft. Unlike a groove, the locking assembly can be moved freely on the shaft.

TAS Schaefer locking assemblies can also be used for existing shafts with a keyway, thus enabling optimization of existing systems.

Series such as the TAS 3015 DK locking element prevent direct movements on the shaft during assembly. This avoids costly damage to the shaft during assembly.

Assembling is performed by inserting the locking assembly between the components and then tightening the clamping screws. The screws must be tightened in a specified sequence and with identical tightening torque. The use of conical surfaces increases the outer diameter and reduces the inner diameter of the locking assembly. Radial pressure is built up.

The clamping forces are provided via the screws (force controlled). This allows the direct compensation of the play between shaft and hub. The locking assemblies of TAS Schäfer GmbH are delivered ready for installation. For a proper function and to achieve a sufficient and even friction value, the contact surfaces of shaft and hub must be clean and provided with an thin oil film.

Corresponding assembly instructions of the clamping sets are provided via the online platform of TAS Schäfer GmbH: TAS Schäfer user manual

The use of locking assemblies is diverse and covers many different industrial sectors. From classic mechanical engineering, as well as conveyor and drive technology, to the packaging and food industries, to name just a few examples. Finally, the locking assemblies enables precise fastening of hubs on shafts or axles, as for example in the fixation of gears and sprockets. In addition, our clamping elements/locking assemblies find applications in conveyor belt drums or crushers. In the food and also petrochemical industry, stainless versions of the locking assemblies are often used in filling or agitating equipment. Locking Assemblies are used in the packaging industry for fastening pulleys and for transporting objects within the machine.

Where to find us

TAS Schäfer GmbH

Osterfeldstr. 75

58300 Wetter (Ruhr)

Fon: +49 (0) 2335 9781-0

Fax: +49 (0) 2335 72956

Mail: info@tas-schaefer.de

Product catalog

Here you can download our latest product catalogue