Product group

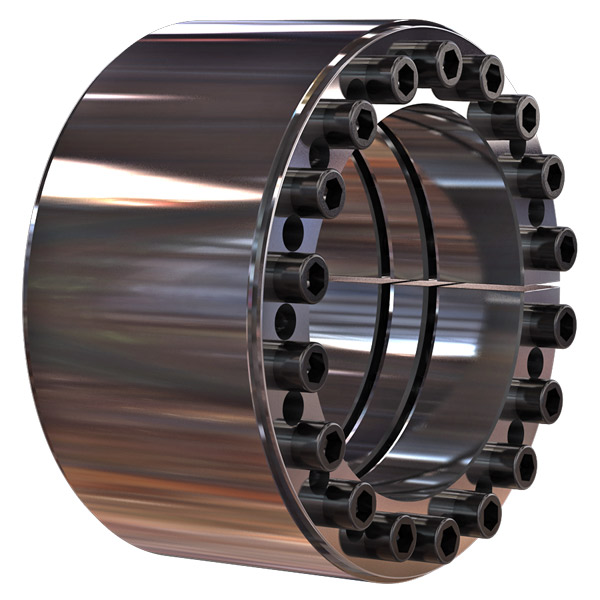

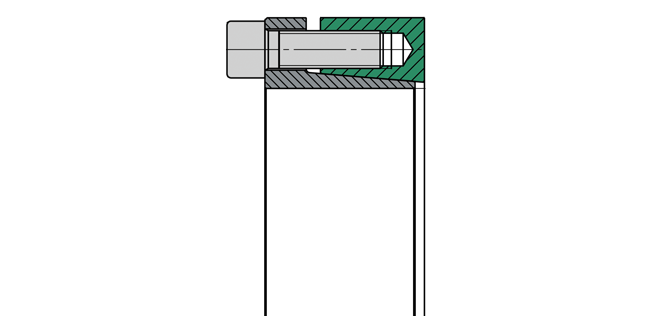

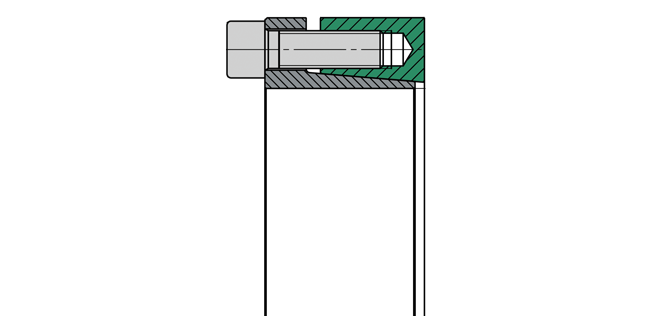

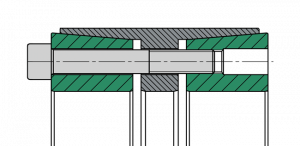

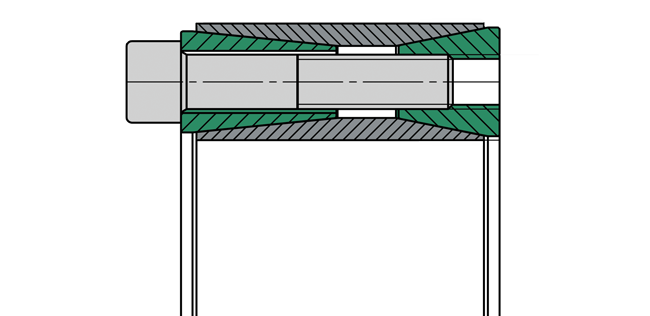

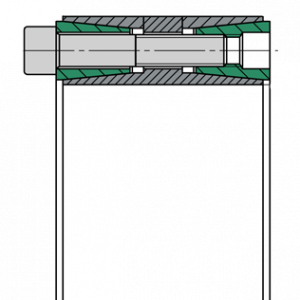

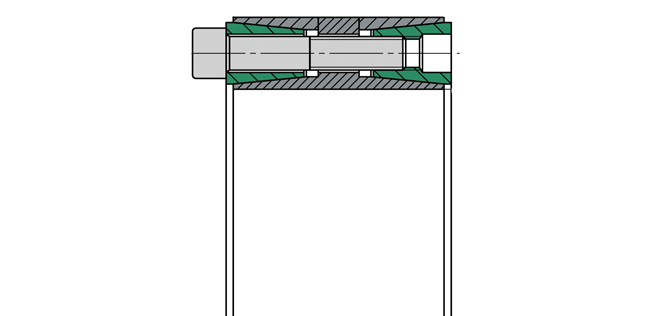

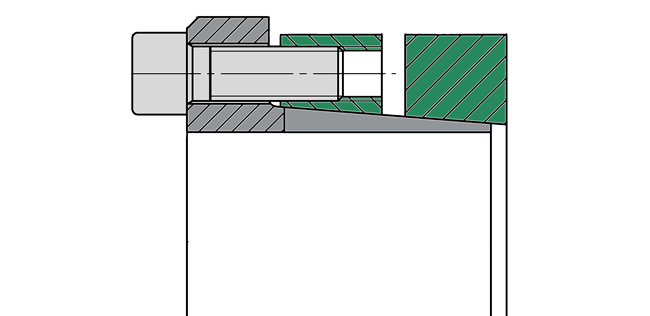

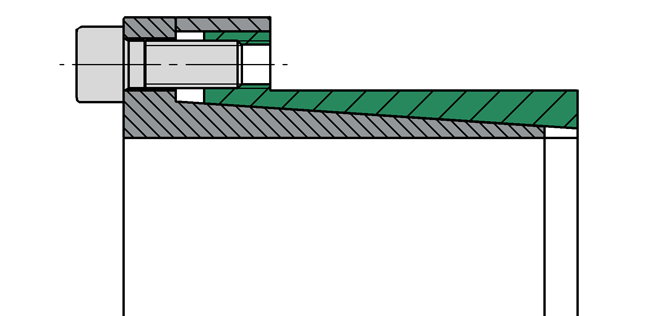

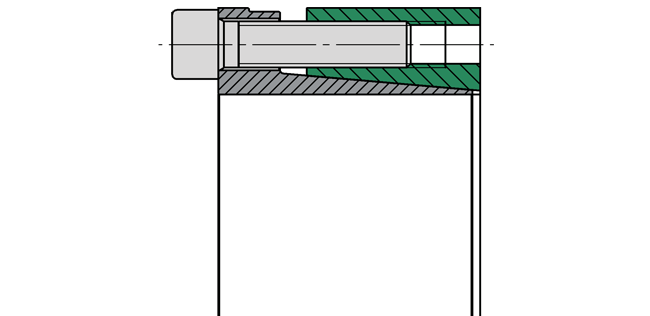

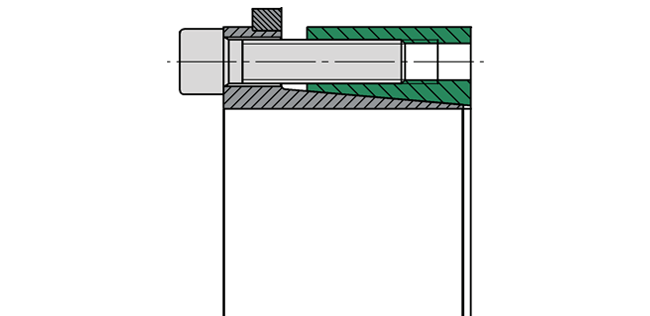

Locking assemblies "Cone Clamping Elements" are internally clamping frictional connecting elements for backlash-free fastening of hubs on shafts. Depending on the design, locking assemblies consist of one or two conical pressure rings and one or more conical clamping sleeves. The conical pressure rings are pulled onto the conical surfaces of the clamping sleeve by tightening the clamping screws to the specified tightening torque and generate a radial force both inwards and outwards at the contact surfaces. This radial force produces a frictional connection between the cone clamping element and the shaft as well as the hub.

By means of this frictional shaft-hub connection, torques and axial forces can be reliably transmitted between the shaft and hub. Depending on the design, bending moments can also be transmitted with this type of connection. Compared to externally clamping connections such as "shrink discs", locking assemblies are located within the force flow. This means that the transmitted forces are passed from the shaft through the locking assemblies into the hub or vice versa. The locking assemblies itself must therefore withstand the forces, as it is the connecting element between the shaft and the hub.

Locking assemblies are available in a wide variety of designs, material and shapes. Depending on the requirements and specifications, we support our customers right from the product selection stage in order to find the perfect product for the application in question. Cone clamping elements are used, for example, to fasten chain wheels, flywheels, levers, belt pulleys, brake discs and conveyor belt drums.

Data sheets or CAD data in various formats can

be requested directly from us

The engineering team of TAS Schäfer GmbH will be pleased to support you already during

the design and product selection in order to find the perfect clamping set for your application.

Where to find us

TAS Schäfer GmbH

Osterfeldstr. 75

58300 Wetter (Ruhr)

Fon: +49 (0) 2335 9781-0

Fax: +49 (0) 2335 72956

Mail: info@tas-schaefer.de

Product catalog

Here you can download our latest product catalogue